INTRODUCTION

The 68Ga isotope is obtained from the 68Ge/68Ga generator at PET centres (Nuclear Medicine) even with the cyclotron in place. The characteristics of the 68Ga isotope that this possesses make it a desirable radionuclide for PET diagnostics and first widely available PET (β+ emitter) radioactive metal ion for routine use worldwide. Due to these serious disadvantages of 68Ga/68Ge generators, such as a very high purchase cost, short expiry date of the generator, low activity of the obtained isotope, 68Ge breakthrough, low availability on the market and the need to a break between successive elutions, the number of PET studies with the use of 68Ga-based radiopharmaceuticals do not meet the market demand [1].

The developed method of [68Ga]GaCl3 via solid target technology in a medical cyclotron at VOXEL S.A. Radiopharmaceuticals Production Center in Kraków, in quality compliant with requirements of the European Pharmacopeia leads to obtain product with a high quality together with a high activity. This may be an attractive alternative to 68Ge/68Ga generators and in the future, by increasing the availability of the 68Ga isotope, may contribute to changing the cancer diagnosis strategy [2].

The 68Ga3+ cation is suitable for conjugation with various biomolecules using bifunctional chelators and various macromolecules, small molecules with fast pharmacokinetic profiles (peptides) due to its relatively small size with an ionic radius of 0.62 Å, which behaves as a relatively hard Lewis acid with binding affinity to oxygen and nitrogen-containing electron donor ligands [3].

OBJECTIVE

Production in regime of Good Manufacturing Practice (GMP) of high quality of 68GaCl3 from a solid target technology in a medical cyclotron will give the product compliant to monography Gallium (68Ga) chloride (accelerator-produced) solution for radiolabelling of European Pharmacopoeia with less than 10 µg/GBq for Zn and less than 10 µg/GBq for Fe with an expiration date of 5 hours towards to leading to Marketing Authorization of gallium chloride as radiopharmaceutical precursor.

MATERIALS AND METHODS

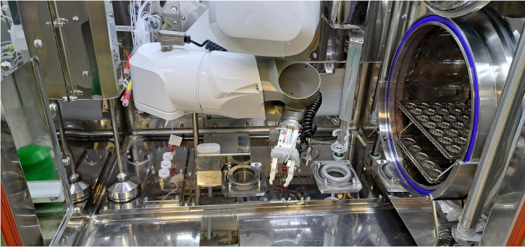

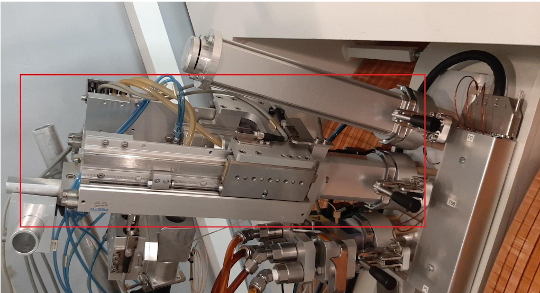

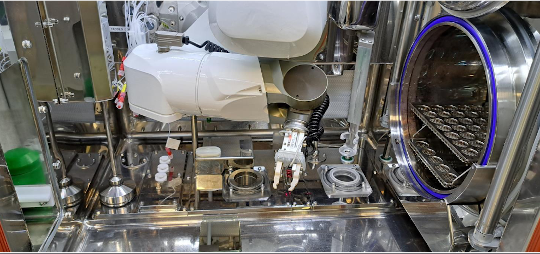

Target is the electroplated enriched zinc (I.E.> 98,0 %) on the shuttle made of platinum (cradle) in amount of 60 mg which is being sent through the pneumatic system. Solid target (Comecer, Italy) is installed at the port of the PETTrace 880 cyclotron (GE,USA) where the irradiation is being made. After irradiation the shuttle is sent to EDS module (Comecer, Italy) for dissolution in a hot concentrated ultrapure hydrochloric acid. After, dissolved irradiated target is sent to Taddeo module (Comecer, Italy) for purification where is loaded on hydroxamate resin to trap 68Ga ion and zinc target material is collected in the recovery vial.

Next the hydroxamate resin is eluted with hydrochloric acid to obtain 68Ga ion which is simultaneously loaded on trioctylphosphine oxide based resin. Next the trioctylphosphine oxide based resin the crude 68Ga is eluted with hydrochloric acid and saline. 68GaCl3 coming from Taddeo purification module has pH=1 therefore there is no need to adjust pH in the dispensing unit where is diluted with ultrapure 0.1M hydrochloric acid. Automatic vial dispenser Theodorico2 (Comecer, Italy) is used. Final radioactive concentration is 500 MBq/ml at the reference date and time.

Diluted and formulated 68GaCl3 is dispensed to the glass vials. Product is terminally sterilized in an autoclave (steam sterilisation). Quality control of the final product - gallium-68 chloride - is performed according to the Ph. Eur. monography, except for the measurements of level of iron and zinc, where the UV-VIS method based on commercially available tests is utilised.

RESULTS

During the trials 33±10 GBq EOB (n=16) of 68GaCl3 were produced which is over ten times greater activity than for the brand new 68Ge/68Ga generator [4]. The highest activites were produced with the high currents of beam. Time and proton current restrictions are set by target manufacturer who works to irradiate the solid target for a longer time with a higher currents. After the trails, three validation runs were produced.

Investigation on glass vials and rubber stoppers was perforemed to check zinc and iron extractables. Each metal parts along the technology line was replaced to plastic to avoid iron or any other metal contamination in the final product. Standard radiolabelling method of DOTATOC and PSMA-11 was performed with no worse yield comparing to radiolabelling these ligands with eluate of 68Ge/68Ga generator.

CTD marketing autorisation dossier was submitted to the Polish Authorities in May 2022. Qualitycontrol results (table 1), show that the final product has a high quality and purity. Quality control analysis was also performed in stress conditions like 2-8°C and 40°C without any impact to quality. Such product can be distributed to Nuclear Medicine facilities out of Kraków’s district where the cyclotron is placed.

| Parameter | Method | Requirements | Result |

|---|---|---|---|

| Appearance | Visual | A clear colourless, free from particles. | conform |

| Identyfication test A | Gamma Ray spectroscopy | The principal gamma peak at 0.511 MeV; 1.077 MeV and/or 1.022 MeV and/or 1.883 MeV | conform |

| Identification test B | Radioactivity measurement | Half-life between 62 and 74 minutes | 67.8±0.0 minutes |

| Identification test C | pH measurement | Not more than 2 | 1.00±0.00 |

| Identification test D | Cation exchange test | The percentage of radioactivity in eluate from strong cation exchange resin not less than 90% | 97±2 % |

| Identification test E | Precipitate test | A white precipitate is formed after adding of silver nitrate solution | conform |

| Radionuclide Purity test A | Gamma Ray spectroscopy | Peaks in the gamma spectrum corresponding to photons with an energy different from 0.511 MeV; 1.077 MeV; 1.022 MeV i 1.883 MeV represent not more than 0.1 per cent of the total radioactivity | 0% |

| Radionuclide Purity test B | Gamma Ray spectroscopy | The total radioactivity due to gallium-66 and gallium-67 NMT 2% at the end of expiry | 0 % |

| Radionuclide Purity test C | Gamma Ray spectroscopy | The total radioactivity due to other gamma-ray- emitting impurities NMT 0,1% | 0 % |

| Chemical purity Test A | UV-VIS Spectrophotometry | Fe, Zn maximum 10 µg/GBq at expiry | Fe: 7±1 µg/GBq Zn: 8±1 µg/GBq |

| Radiochemical purity test B | TLC | [68Ga] gallium (III) ion: minimum 95 % | 100±0 % |

| Bacterial Endotoxins | LAL test | Not more than 35 IU/ml | 5.76±1.38 IU/ml |

| Radioactivity content | Radioactivity measurment | 90% to 110% of declared gallium-68 radioactivity at time and date stated on the label | 96±1 % |

| Sterility | Ph. Eur. | Sterile | Sterile |

SUMMARY AND CONCLUSIONS

The 68Ga isotope method of production via solid target technology is characterised by a big amount of product with a high quality and purity. The liquid target and 68Ge/68Ga generator eluate have a 10 times lower acivities than solid target production [4]. One batch of 68GaCl3 can be distributed to three locations with the activity of about 2 GBq in 5 ml solution.

This technology is carried out with good yields, repeatability, purity and in quality compliant with the requirements of the European Pharmacopoeia [5], Good Manufacturing Practice (GMP) and managed to First in Europe Marketing Autorization from solid target of gallium chloride as radiopharmaceutical precursor, V-Ga68 500 MBq/ml.

REFERENCES

[1] F. Alves, et. al., Modern Physics Letters A, 32, 17, (2017).

[2] A.H. Alnahwi, et. al., Applied Radiation and Isotopes, 156, 109014, (2020).

[3] K. Kumar, Cancer Biotherapy and Radiopharmaceuticals, 35, 3 (2020).

[4] B. J.B. Nelson et .al., Nuclear Medicine and Biology 80–81 (2020).

[5] Gallium (68Ga) chloride (accelerator produced) solution for radiolabelling. European Pharmacopoeia. 2020;10 (Suppl. 10.3):4864–4865.

J. Boratyńskia,b, M. Jagodzińskia,b, M. Pilch-Kowalczyka, Z. Rogulskib aRadiopharmaceutical Production Center, VOXEL S.A, ul. Wrocławska 1-3, 30-006 Kraków, Poland

bFaculty of Chemistry, Universisty of Warsaw, ul. Żwirki i Wigury 101, 02-089 Warszawa, Poland

E-mail: j.boratynski@voxel.pl

This work was supported by the project number RPMP.01.02.01-12-0609/18-00 titled: „Conducting development works aimed at implementing an innovative technology of a new line of radiopharmaceuticals”, cofinanced by Regional Operational Program of the Lesser Poland Voivodeship

- Dodaj komentarz

- 172 odsłony

Komentarze

Dodaj komentarz